Our means of production When a beehive comes alive ...

Our workshops

Our core business, layout, is also a core business. All of our Workshop Fellows share a passion for it. With nearly 16,000 m2 of production area spread around the world, they benefit from state-of-the-art digital equipment: 4 and 5-axis machining centers, complete nesting platform, very high capacity panel storage units, tackle … Experienced, our Compagnons develop transversal know-how in all phases of manufacturing, guarantee traceability and ensure themselves continuous control, down to the part.

- Traditional cabinetry

- Fine metalwork

- The resin workshop

- The finishing workshop

- The special production workshop

- The plating workshop

- Serial workshops

Traditional cabinetmaking

Since its creation, the CAA Group has always maintained a deep attachment to cabinetmaking and traditional techniques. In his workshops dedicated to solid wood, his companion cabinetmakers work in the pure tradition and always resort to manual gestures. They use all types of wood and respond to requests for restoration, copy of old, realizations of openings, traditional oak woodwork, patinated traditional woodwork, brick partitions, wall decorations, showcases, works of excellence in all types of decoration. ‘essences.

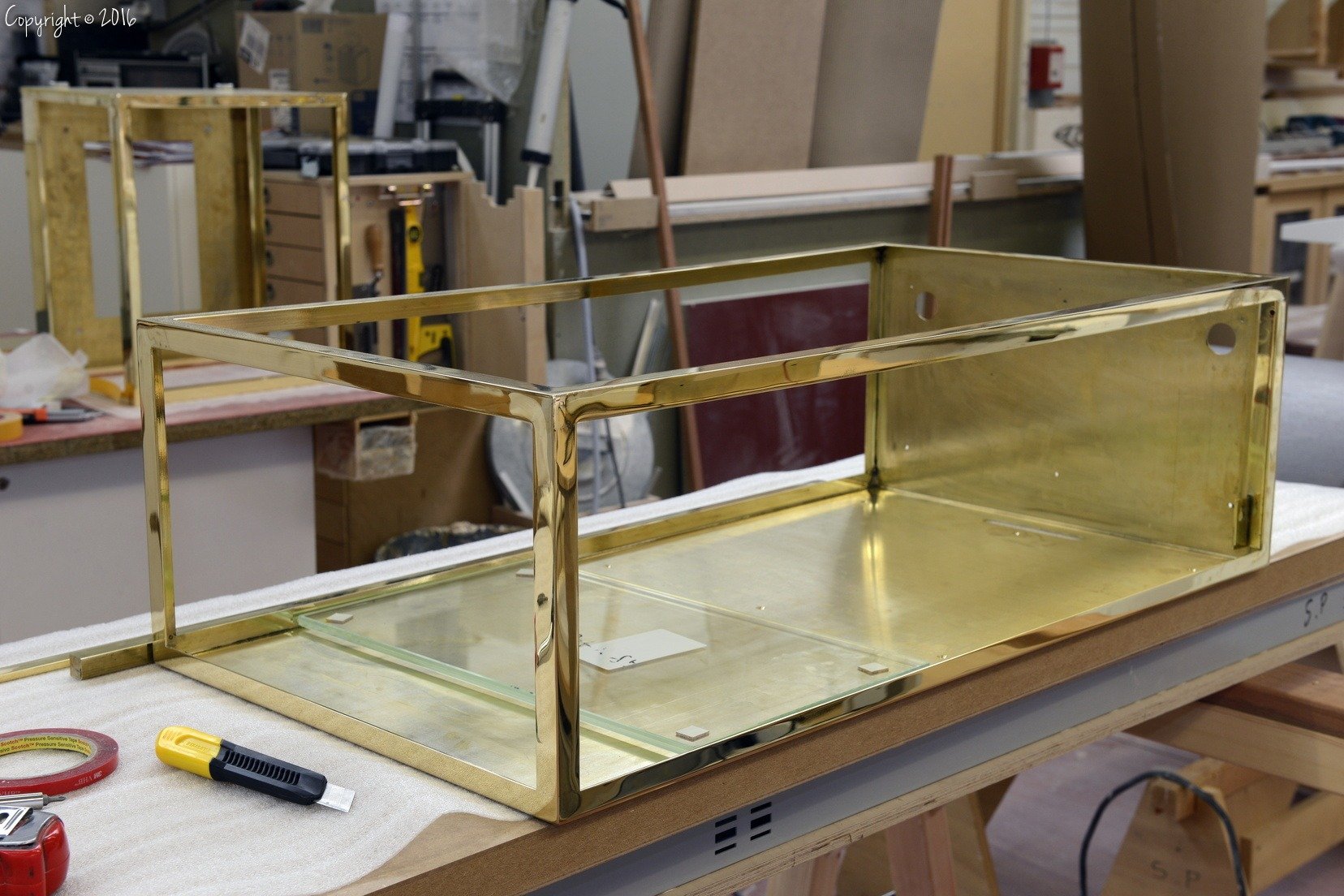

Fine metalwork

Clever dressings, custom finishes

At the headquarters of the CAA Group, our main production unit has a fine metal workshop equipped with a folder, a shear, a digital press and a waterjet cutting center. and sand. It brings together a seasoned team of welders, polishers and professional metalworkers who internally provide structural and cladding services with all types of finishes: microblasted stainless steel walls, bar facades, mirror polished display cases, steel ornaments, powder coatings, varnishes. , patinas, aged brass, high precision polishing.

The Resin Workshop

Our Resin Workshop is equipped to thermoform and obtain the most complex deformations. At headquarters, we devote an area of 1,500 m2 to solid surfaces. We obtain deformations of the order of 180% and can exert pressures of 800 bars per cm2, without breaking the material. The variety of possible implementations offers particularly innovative decorative solutions. Curved, sculpted, inlaid, printed, textured, veined, glittered, or even assembled with other materials, the resin bends to the most fertile imaginations and offers the most sophisticated shaping possibilities.

The finishing workshops

All of the CAA Group’s manufacturing units have fully equipped lacquer and varnish finishing workshops, including digital for high quality finishes. Our Compagnons develop their own formulas and accumulate many jealously guarded “trade secrets”. Wood, metal, resin, glass and even natural stone finishes are carefully implemented, internally, by highly qualified teams. From color matching to the application of satin, matte, glossy lacquers and all shades, the results are down to the shade.

Special manufacturing workshops

Reserved for complex and non-standard works, our special Fabrications Workshops are those of tailor-made, very high-level personalization and masterful pieces. Our Compagnons carry out monumental works, unique examples and the most spectacular architectural challenges. The assembly of materials and the integration of special functions are also carried out with particular care.

Plating Workshops

Our Veneer Workshops offer a very wide range of wood or laminate coatings. Oak, walnut, maple, burl, beech and all species without exception can be applied to the panels. Concerned about respecting the measures in favor of the environment taken by the CAA Group, our Compagnons develop their own sizing formulas, using aqueous bases in the context of the avoidance of solvents.

Serial workshops

Equipped and structured to meet large series demands, these workshops with specific organizations ensure serial production that reconciles rates, calendar requirements and consistency in the quality of furniture and fittings. In conjunction with our integrated logistics service, our teams are able to ensure national and international deployments, including simultaneously. A rigorous traceability system and the practice of continuous monitoring guarantee constant quality from part to part. Our serial productions with large accounts are managed by intranets dedicated to each brand or group, in order to report in real time.